WASP®

Walk-Away Specimen Processor for Microbiology

Product Overview

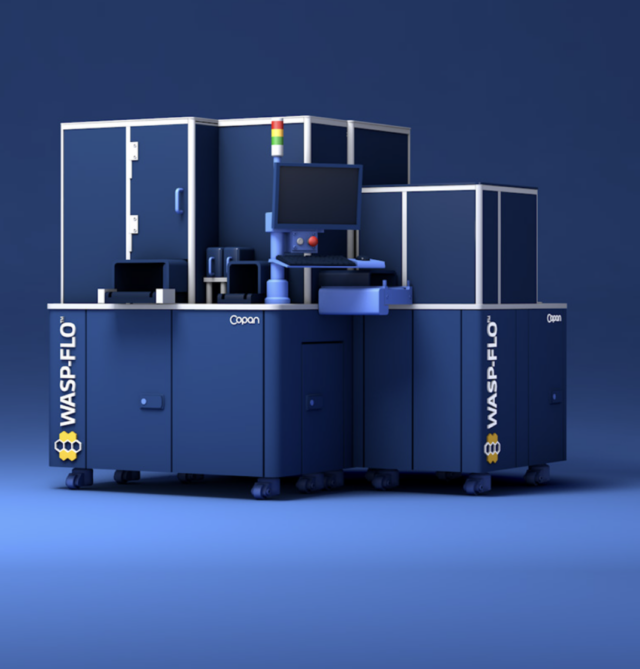

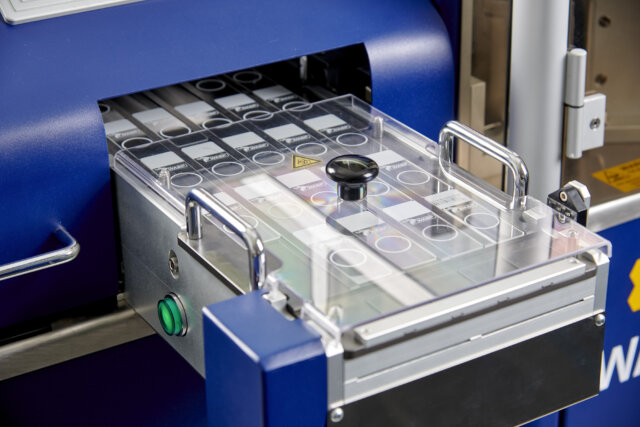

WASP® is a modular, open platform that fully automates all facets of specimen processing in Microbiology, including planting and streaking, Gram slide preparation, broth inoculation and disk application to aid in rapid, direct identification.

- Automates planting & streaking, Gram-slide preparation, and more

- Modular, open-platform design connects with any LIS

- Helps laboratory technicians to manage tremendous workload

WASP® streamlines specimen processing allowing laboratory professionals to focus on tasks requiring their specialized skills.

Walk-Away Specimen Processing

Automates accessioning, planting, streaking, slide prep, broth inoculation, and disk application allowing reassignment of technicians to higher complexity tasks 1

Standardize Best Practices

Designed to replicate experienced technologist's work, following guidelines and standards for consistent, optimal specimen setup.2-3

Minimize Operational Costs

Reusable metal loops reduce operational cost and waste disposal expenses.

Improve Specimen Traceability

Labels plates, slides, and broths then reconciles with LIS ensuring end-to-end traceability.

Walk-Away Specimen Processing

WASP® streamlines specimen processing, including planting, streaking, slide preparation, and labeling, allowing laboratory professionals to focus on tasks requiring their specialized skills.

- Load specimens randomly without pausing equipment

- Universal decapper automatically handles various container types

- Save time with seamless automatic accessioning of specimens into the LIS

Ensure Optimal Specimen Setup

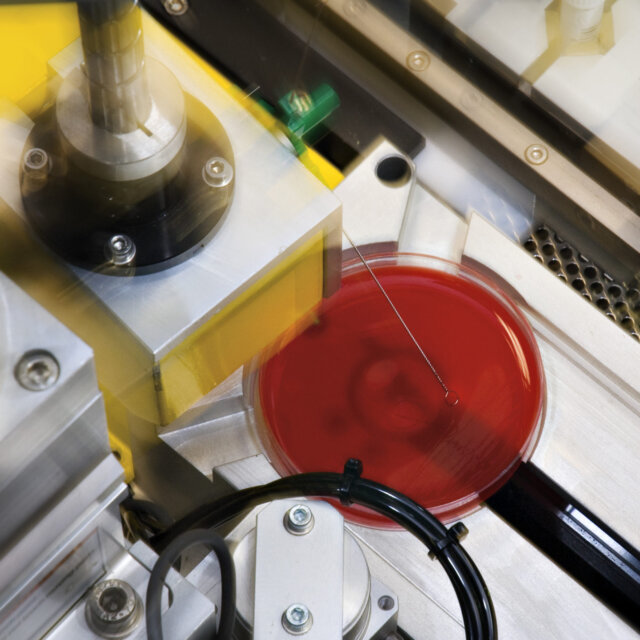

The system confirms inoculum presence using image analysis and automatically chooses the optimal loop size (1µl, 10µl, or 30µl). WASP® features a comprehensive streak pattern library and offers loop sterilization between quadrants for superior colony isolation.

Minimize Operational Costs

The system’s reusable metal loops slash operational costs and waste disposal expenses. Its fully electric design removes the need for costly compressors. Open platform compatibility offers users a choice in culture plate brand for greater flexibility and cost savings.

Maximize Automation Investment

Copan’s recommends Liquid Based Microbiology (LBM) product line, which allows all specimens to be liquefied and made ready for automation. However, non-liquid samples or traditional swabs can certainly be managed using the WASP® streak only function. Learn more about the first step to automation and simplified collection and processing for almost all specimens that come into your laboratory:

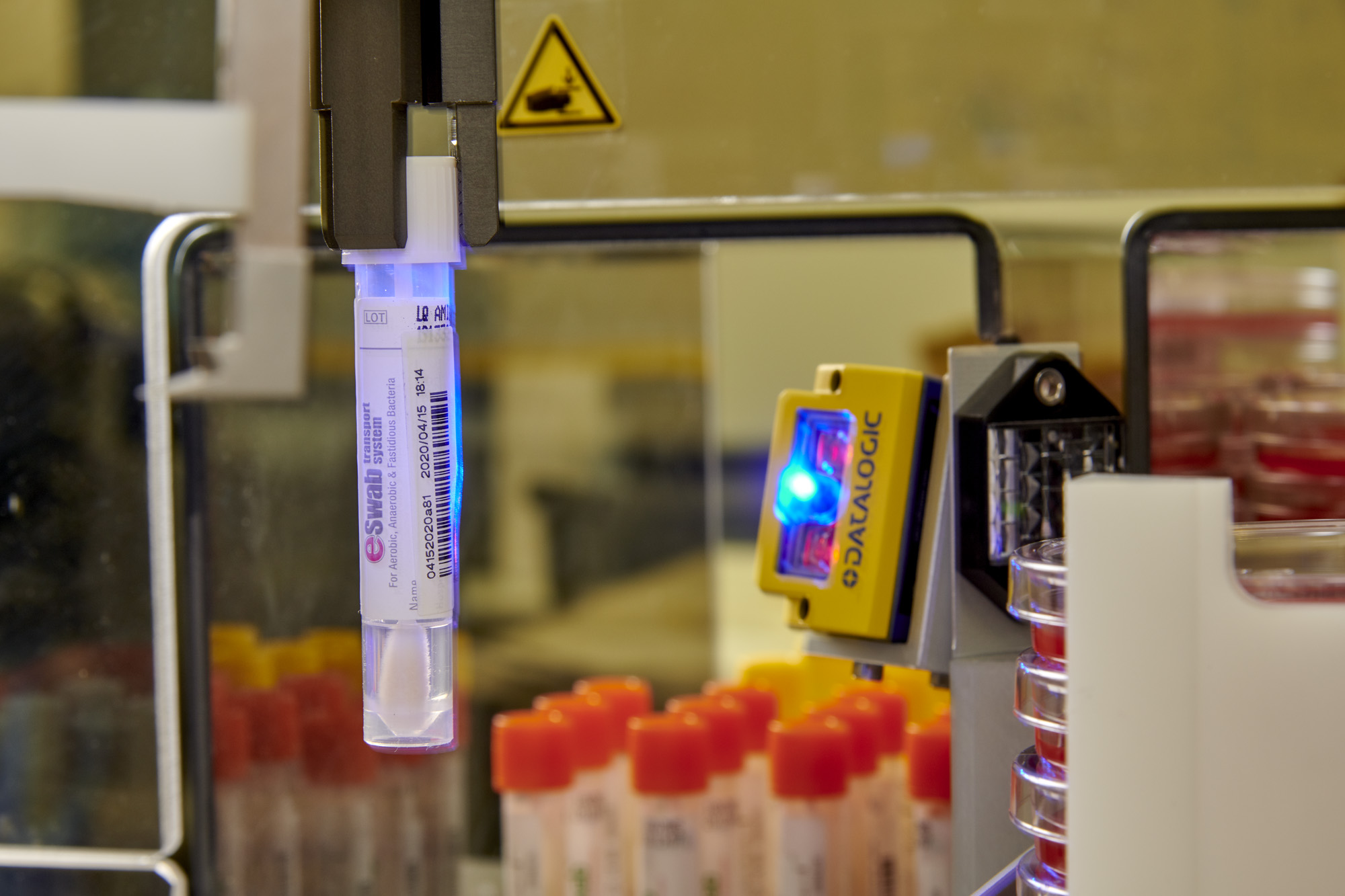

ESwab® Liquid Based Collection and Transport

ESwab® is Copan's multipurpose collection and transport system pairing our patented FLOQSwabs® with Liquid Amies Medium for superior bacteriology collection and transport.

FecalSwab® System for Enteric Bacteria

FecalSwab® simplifies stool collection by pairing FLOQSwabs® with Cary-Blair medium to liquify samples for improved recovery of enteric bacteria.

SnotBuster™ Sputum Liquefying Solution

The SnotBuster™ system liquefies sputum specimens prior to culturing for the isolation of bacteria and fungi, without affecting morphology, growth or microscopic staining.

Selective Enrichment Broths

Copan’s Selective Enrichment Broths in plastic tubes are specifically designed for WASP®, decreasing manual handling and maximizing automation utilization.

Future-Proof Flexibility

The system is forward compatible and designed to grow with your laboratory over time. As your needs change and expand, the core WASP® system can be expanded to include Full Laboratory Automation and Artificial Intelligence software algorithms.

Enhanced Traceability with Barcode-Driven Technology

WASP®’s advanced 360° scanning technology accurately reads barcodes on specimen containers from any angle. The system distinguishes and interprets multiple labels and barcode languages on a single tube. LIS integration ensures patient specimen barcodes are consistently matched with labels on plates, slides, and inoculation tubes.

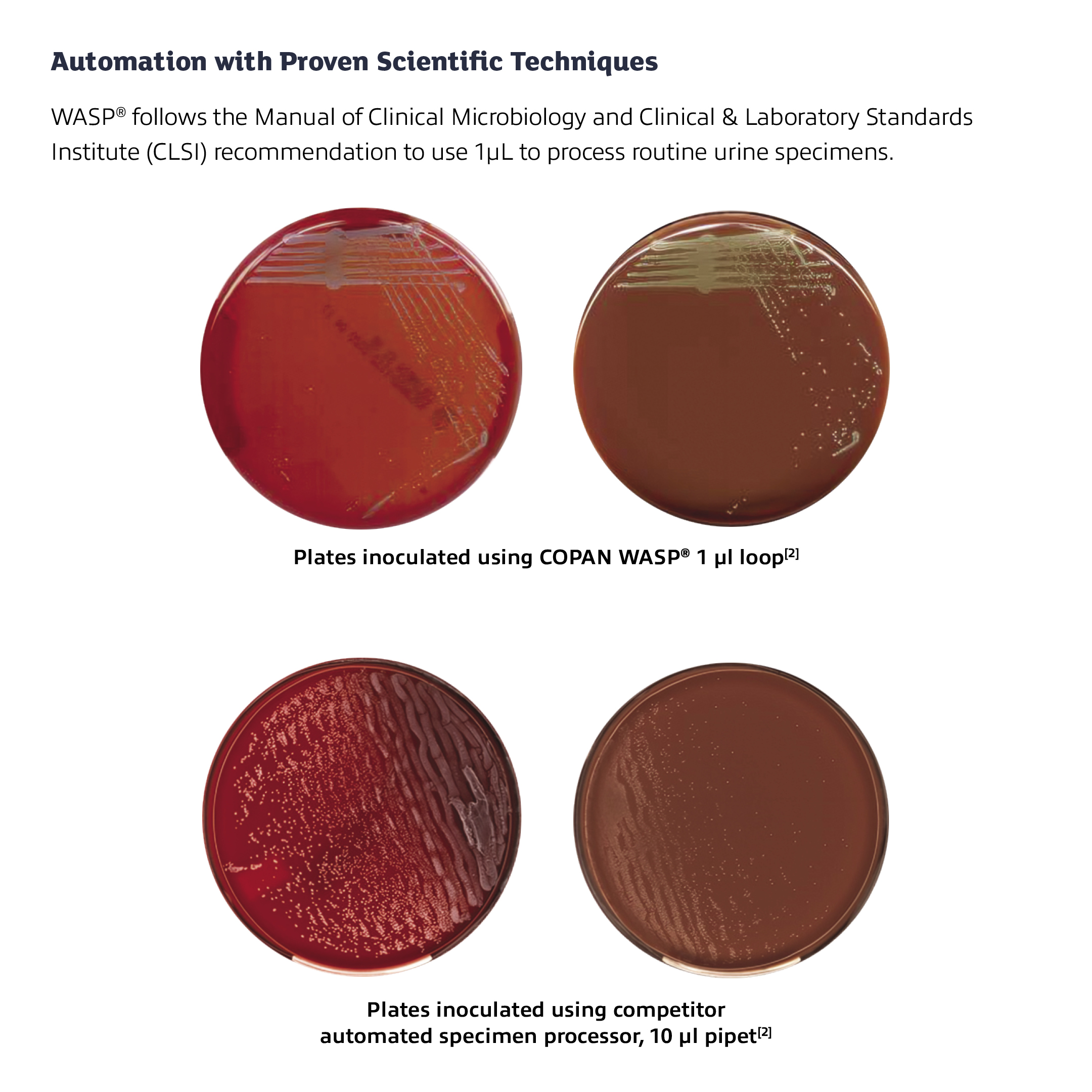

The Difference is Clear - Automation with Proven Scientific Techniques in Mind

WASP® follows the Manual of Clinical Microbiology and Clinical & Laboratory Standards Institute (CLSI) recommendation to use 1μL to process routine urine specimens.

Eliminate Contamination Risk

HEPA filtration continuously circulates clean air within the instrument’s critical work environment. Individualized specimen management, containment, and confinement measures ensure a clean work environment.

Not Just an Automated Specimen Processor, but a Partner for the Future

Copan’s commitment to collaboration shapes the evolution of over 1300 WASP® instruments globally. Emphasizing human partnership alongside technological advancement, we collaborate closely with the microbiology community. This approach fosters trust and reliance among laboratories worldwide, ensuring continuous innovation in automated specimen processing.

Additional WASP® Modules

Broth and Disk Module

Complete specimen processing with automatic enrichment broth and AST disk dispensing module.

Gram SlidePrep™ EVO

Automatically prepare Gram slides, including laser printing of the patient identifiers.

Dual loop

Maximize throughput by simultaneously streaking both sides of bi-plates.

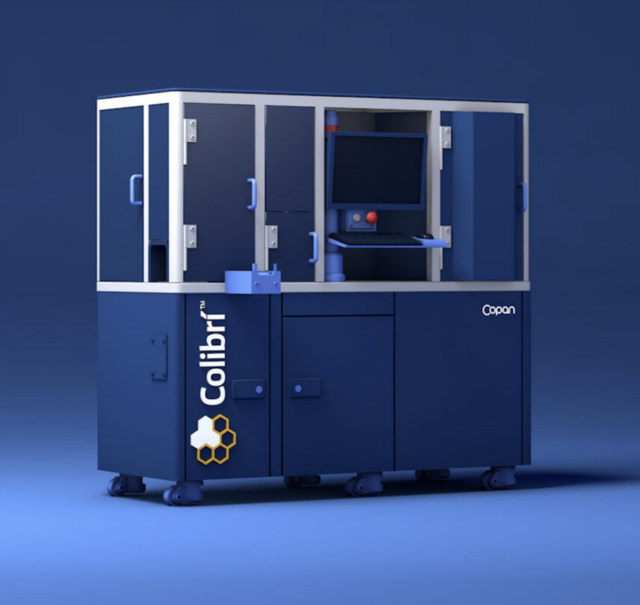

We help you begin your automation journey

Copan delivers full laboratory automation innovations spanning specimen sorting, processing, smart incubation, specialized imaging, and AI interpretation to maximize clinical microbiology productivity. Our modular platforms are uniquely customized to each laboratory while enhancing quality, safety, and traceability.

References & Citations

1. Kim J. ADLM. 2023. Understanding Laboratory Automation in Clinical Microbiology

2. Doern GV, et al. MCM. 2015. Automation and Design of the Clinical Microbiology Laboratory

3. Antonios K, et al. Clin Chem. 2022. Current State of Laboratory Automation in Clinical Microbiology

Resources and Downloads

WASP®

Resources and Downloads

Our Promise

Copan is committed to innovation in preanalytics. The automation developed by the COPAN team helps Microbiologists to provide faster and better results, and ultimately to make a difference and have a strong impact on patient care.