WASP® FAQ

The WASP® FAQ is a comprehensive guide that provides detailed information about Copan's automated microbiology specimen processing system, covering key topics such as capabilities, advantages, technical specifications, quality control, integration, and cost considerations.

Contents

- What is the Copan WASP® system?

- What tasks can the WASP® System automate?

- What are the key advantages of using WASP® in the microbiology lab?

- What is the capacity of the WASP® system?

- Can WASP® be customized to meet specific laboratory requirements?

- Can WASP® handle different types of specimen containers and barcodes?

- Can WASP® process non-liquid samples?

- What types of culture media can be used with WASP®?

- How does WASP® ensure optimal specimen inoculation?

- What is the role of the inoculation verification camera in WASP®?

- How does WASP® handle different streaking patterns?

- What measures are in place to prevent cross-contamination in WASP®?

- Can WASP® be expanded with additional modules?

- How does WASP® ensure accurate labeling of plates, slides, and tubes?

- Can WASP® be integrated with other laboratory automation systems?

- How does WASP® handle reject specimens or processing errors?

- How does WASP® contribute to reducing costs in the microbiology laboratory?

- How can laboratories evaluate the potential return on investment (ROI) for WASP®?

- What support and training does Copan provide for laboratories implementing WASP®?

- How does WASP® fit into Copan's vision of full laboratory automation?

- Do You Have Other Questions about WASP® FAQ?

What is the Copan WASP® system?

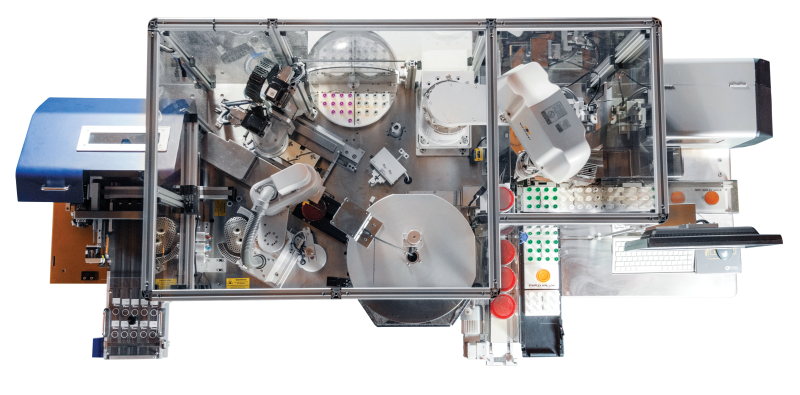

WASP® (Walk-Away Specimen Processor) is a modular, open-platform automation system for microbiology laboratories. It fully automates various aspects of specimen processing, including planting, streaking, labeling, Gram slide preparation, broth inoculation, and disk application.

What tasks can the WASP® System automate?

The WASP® System automates several key tasks in the microbiology laboratory, including:

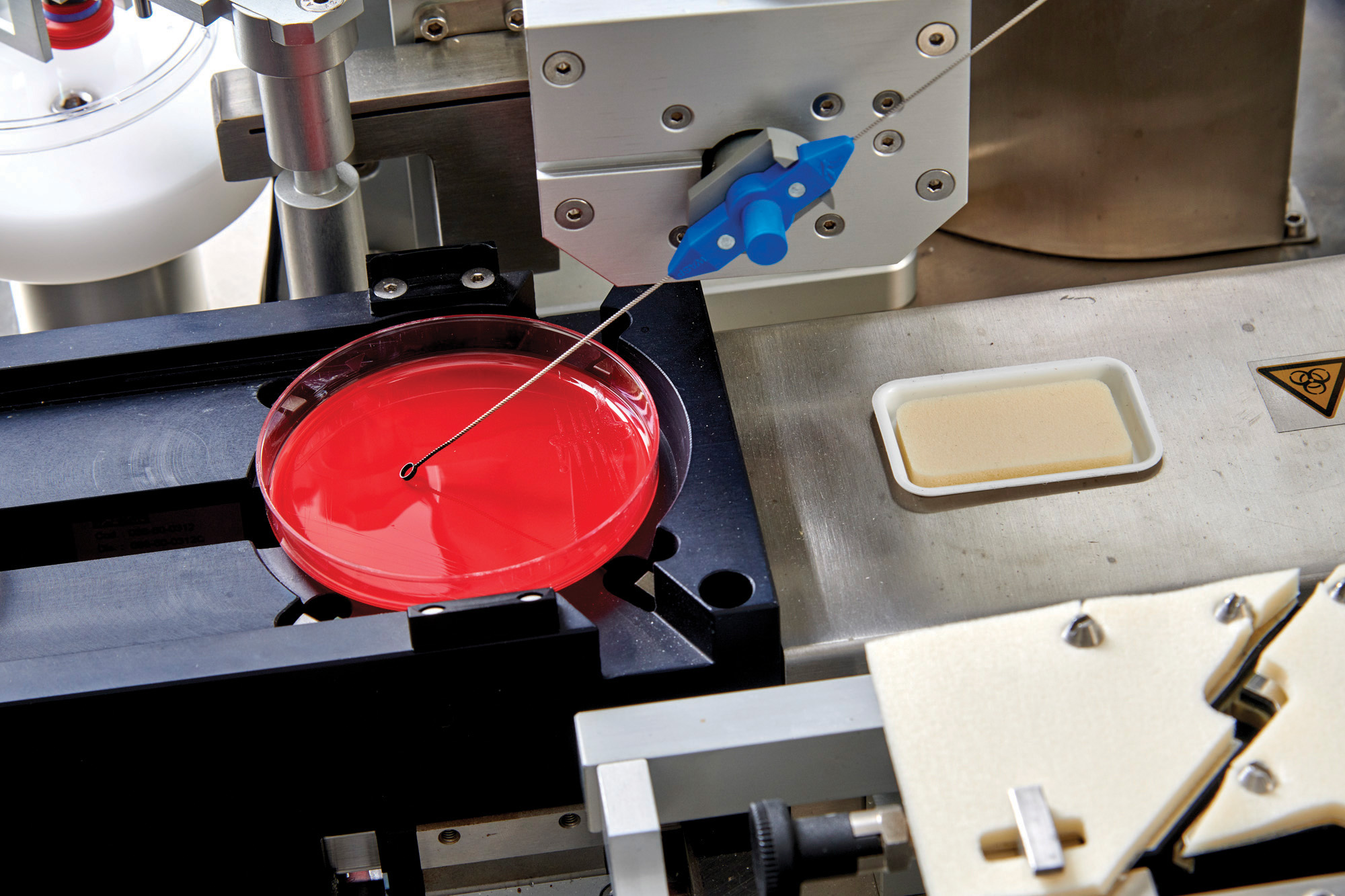

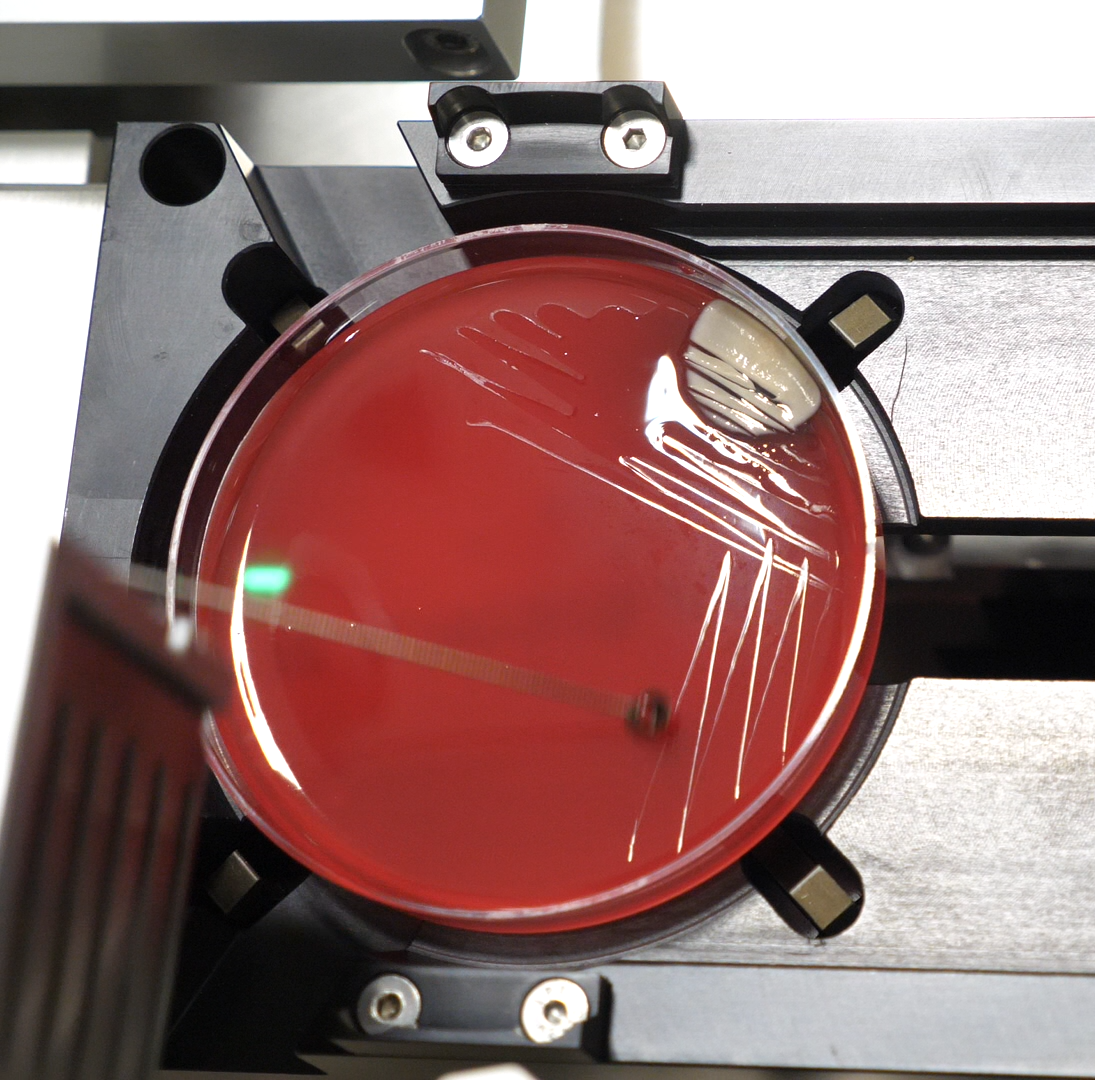

- Planting and Streaking: Automated inoculation and streaking of samples onto agar plates.

- Gram Slide Preparation: Automatic preparation of slides for Gram staining.

- Broth Inoculation: Precise inoculation of specimens into broth media.

- Label and Reconcile: Applies custom labels to output plates, slides and tubes and synchronizes with LIS for full traceability.

What are the key advantages of using WASP® in the microbiology lab?

WASP® streamlines specimen processing, allowing laboratory professionals to focus on tasks requiring their specialized skills. It standardizes best practices, minimizes operational costs, improves specimen traceability, and ensures optimal specimen setup.

WASP® offers several significant benefits, including:

- Increased Productivity: Allows labs to process more specimens in less time with reduced manual intervention.

- Consistent Results: Standardizes specimen processing to ensure consistent and reliable results.

- Labor Optimization: Frees up skilled staff to focus on interpretive and analytical tasks rather than routine specimen processing.

- Enhanced Quality Control: Reduces the risk of cross-contamination and improves overall process control.

- Potential for Cost Savings: Through increased productivity and reduced consumables and waste.

What is the capacity of the WASP® system?

The WASP® system is designed for high-throughput processing, with a media carousel that can hold up to 378 plates. The specimen entry conveyor allows for continuous loading of samples without the need for batching, further enhancing the system’s efficiency and throughput.

Can WASP® be customized to meet specific laboratory requirements?

Yes, WASP® offers a high degree of customization to accommodate different laboratory workflows, specimen types, and processing protocols. The system’s modular design allows for the addition l of components, such as the optional Gram SlidePrep™ or the broth inoculation turntable, based on the laboratory’s needs.

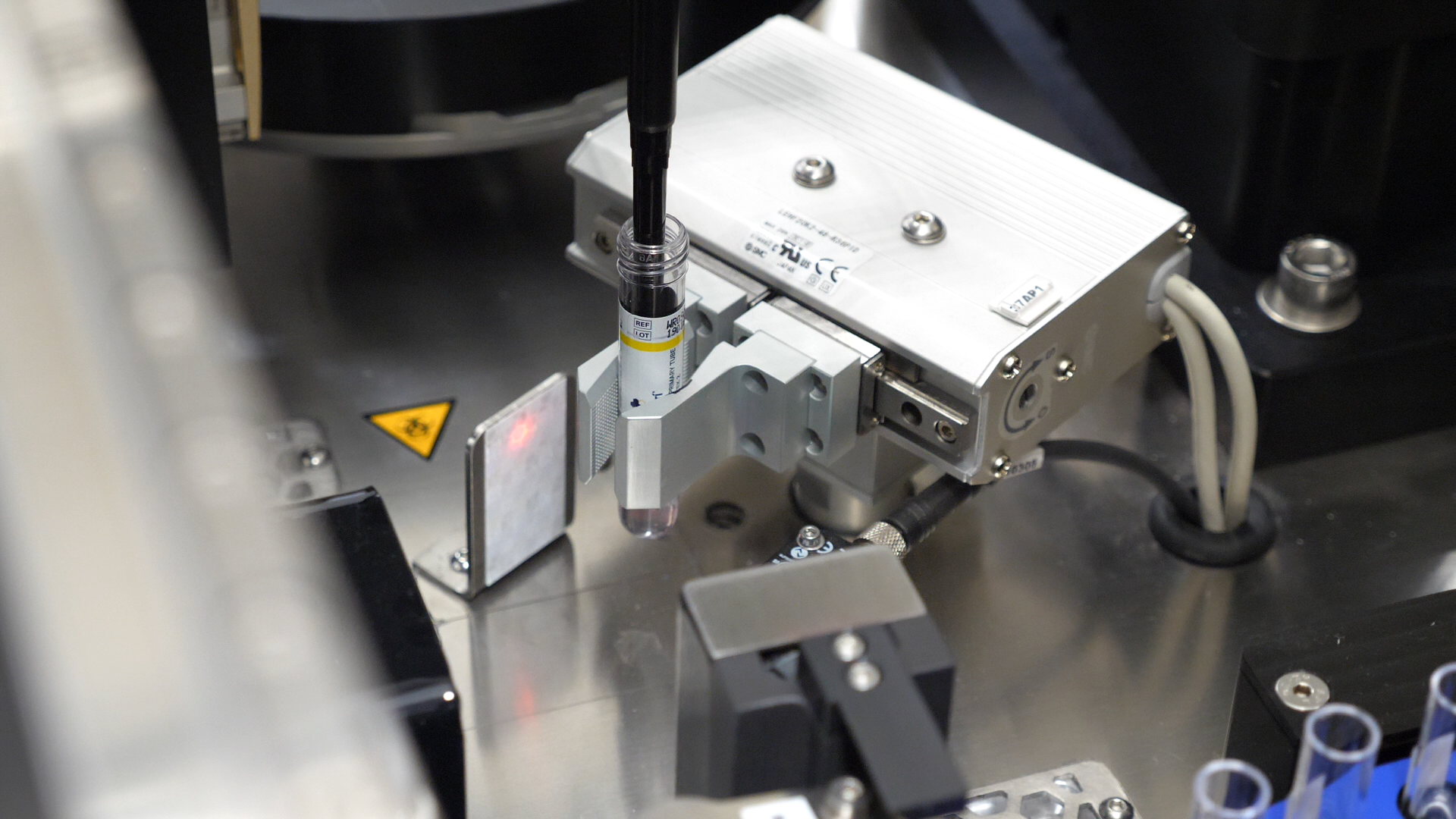

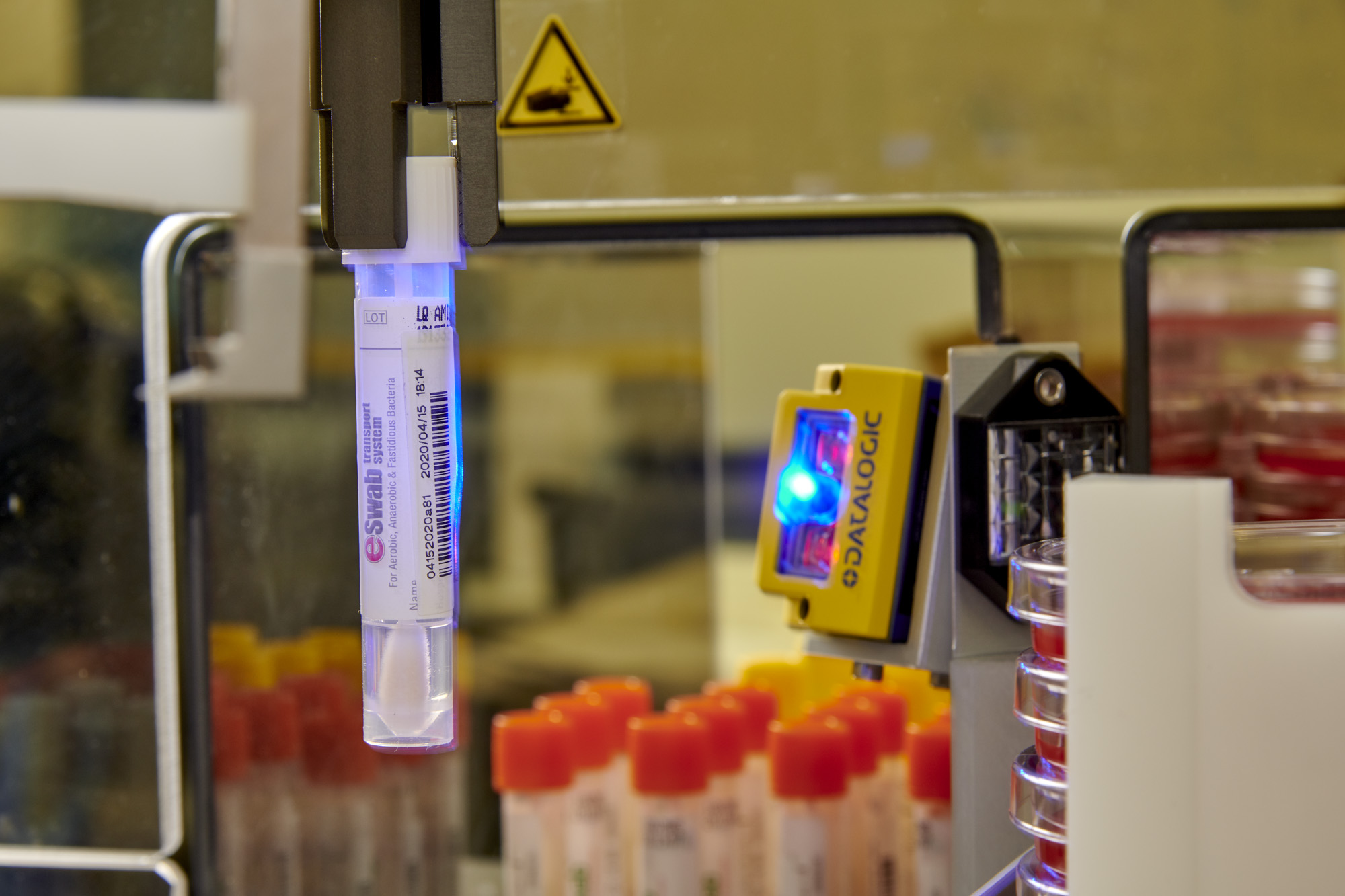

Can WASP® handle different types of specimen containers and barcodes?

Yes, WASP® features a universal decapper that automatically decaps and recaps various tube types. Its advanced barcode reading technology can interpret multiple labels and barcode languages on a single container, reading them from any angle.

Can WASP® process non-liquid samples?

While Copan recommends using Liquid Based Microbiology (LBM) products for optimal automation, WASP® can also process non-liquid samples or traditional swabs using the streak-only function.

What types of culture media can be used with WASP®?

WASP® is an open-platform system, which means it can accommodate culture media from any manufacturer. This flexibility allows laboratories to choose the media that best fits their needs and budget.

How does WASP® ensure optimal specimen inoculation?

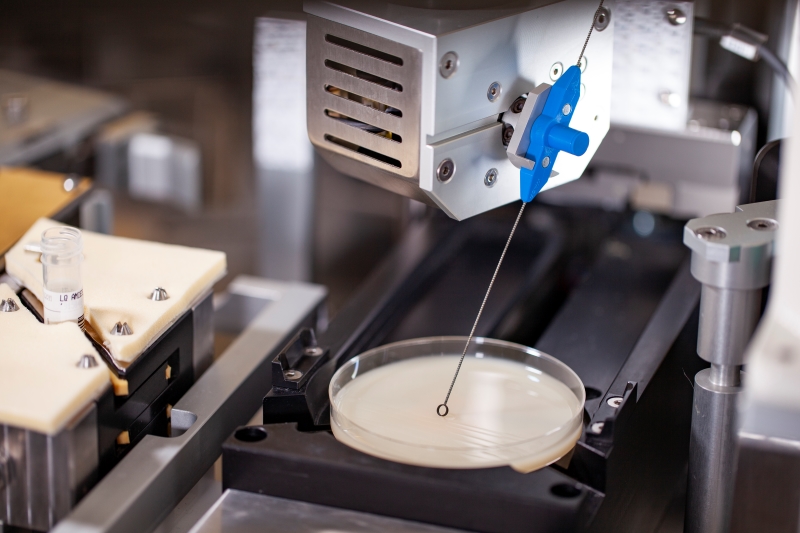

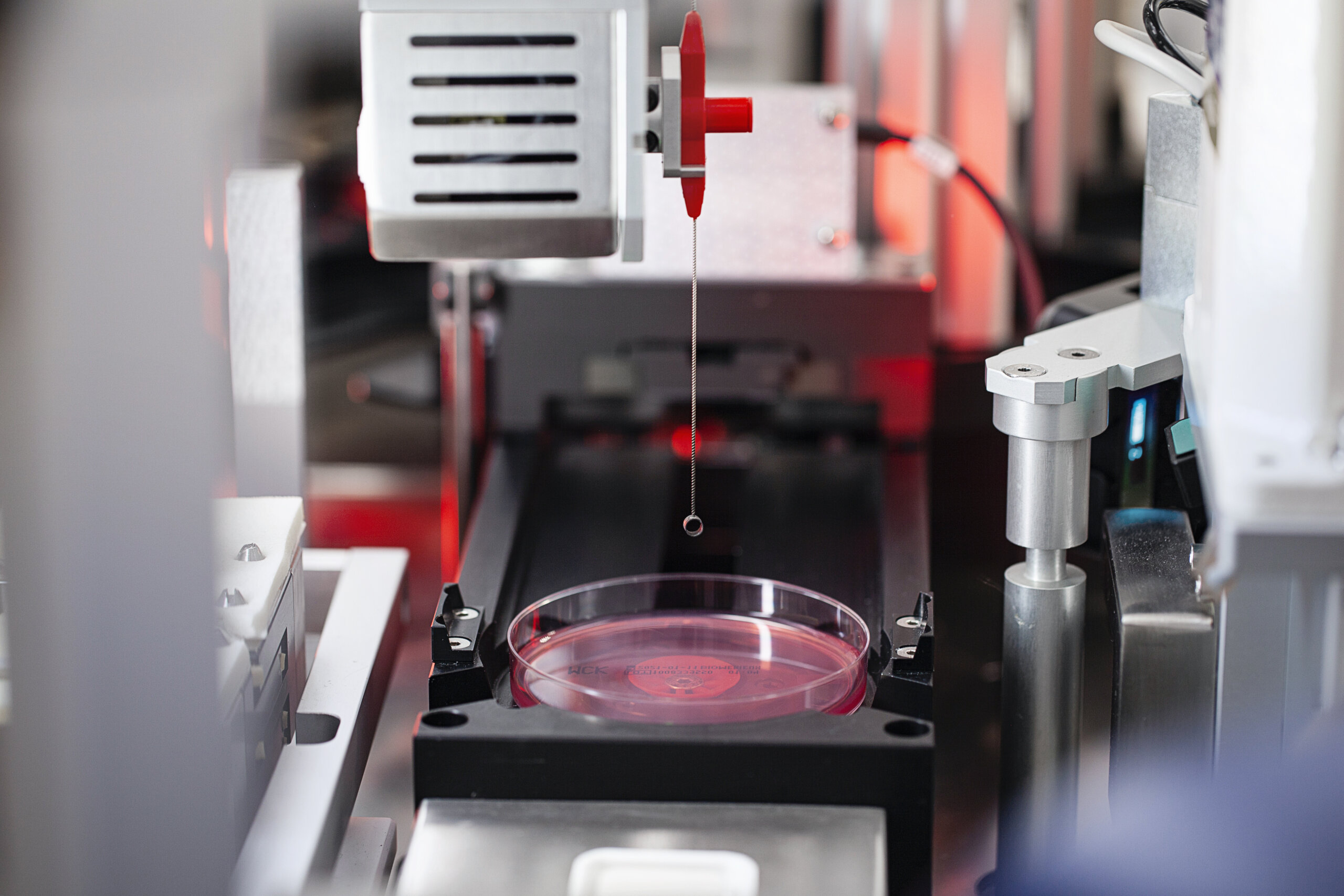

WASP® confirms inoculum presence using image analysis and automatically selects the appropriate loop size (1µl, 10µl, or 30µl). The system offers a comprehensive streak pattern library and loop sterilization between quadrants for superior colony isolation.

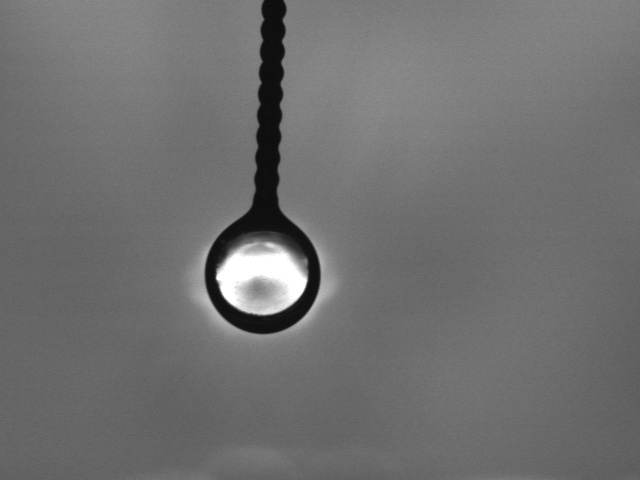

What is the role of the inoculation verification camera in WASP®?

The inoculation verification camera in WASP® serves two key functions:

- It checks the presence of the inoculum on the loop to ensure that the sample has been successfully picked up, and

- It verifies the integrity of the inoculation loop itself, detecting any potential damage or carbon build up from the sterilization process.

How does WASP® handle different streaking patterns?

WASP® offers a comprehensive library of over 40 streaking patterns. The appropriate pattern can be automatically selected based on the specimen type and LIS instructions, ensuring consistent and optimal isolation of colonies.

What measures are in place to prevent cross-contamination in WASP®?

WASP® features a HEPA filtration system and anti-drop technical solutions to minimize contamination risks. It also employs individualized specimen management, containment, and confinement measures.

Can WASP® be expanded with additional modules?

Yes, WASP® is designed to be future-proof and can be expanded with modules such as the Broth and Disk Module for enrichment broth and AST disk dispensing, and the Gram SlidePrep™ for automated Gram slide preparation.

How does WASP® ensure accurate labeling of plates, slides, and tubes?

WASP® features an integrated printer that automatically labels plates, slides, and inoculation tubes. The system’s software reconciles these labels with the patient specimen barcode, ensuring end-to-end traceability and reducing the risk of errors.

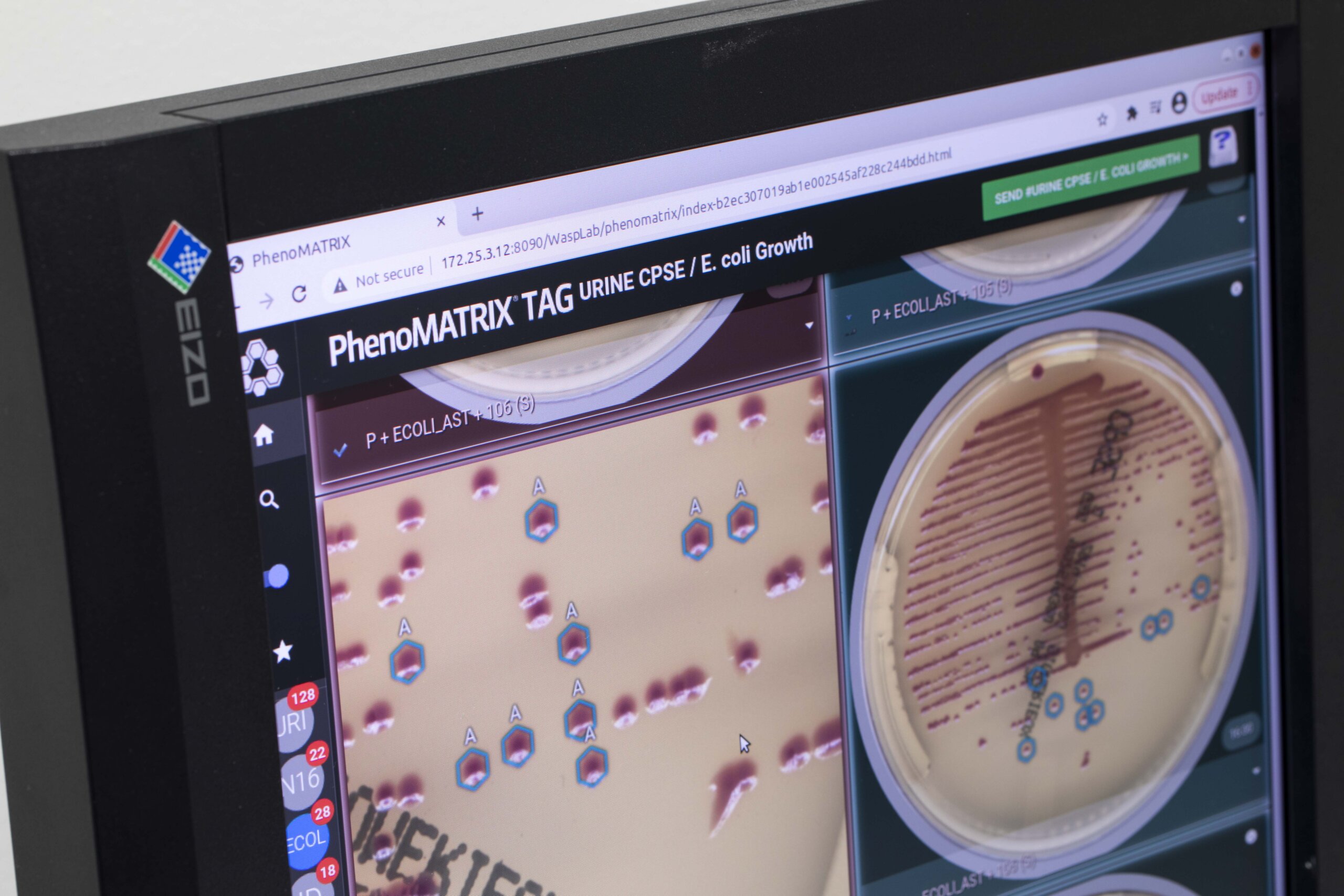

Can WASP® be integrated with other laboratory automation systems?

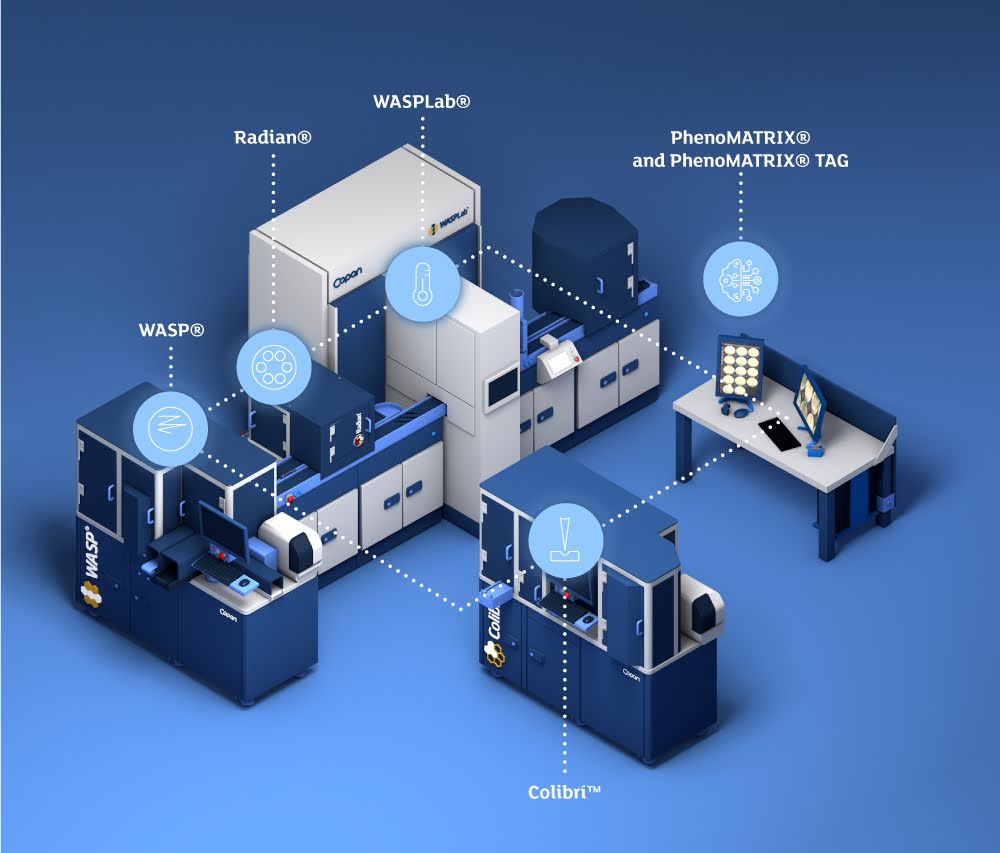

Yes, WASP® is designed to integrate with other components of the WASPLab® system, PhenoMATRIX®, and Colibrí™. This integration enables end-to-end automation of the microbiology workflow, from specimen processing to incubation, imaging, and interpretation.

How does WASP® handle reject specimens or processing errors?

WASP® has a dedicated reject bin for segregating specimens that do not meet the processing criteria or encounter errors during the workflow. This helps maintain the integrity of the processing workflow and allows for easy identification and management of problematic samples or deformed labeling.

How does WASP® contribute to reducing costs in the microbiology laboratory?

WASP® helps reduce costs in several ways:

- Automating manual tasks allows for the reallocation of staff to higher-value tasks improves overall laboratory productivity

- Standardizing processes minimizes the risk of errors and the associated costs of repeat testing

- The use of reusable inoculation loops reduces waste and disposal costs.

How can laboratories evaluate the potential return on investment (ROI) for WASP®?

Factors to consider when assessing ROI include current specimen volumes, staffing requirements, consumable costs, and error rates. Copan provides tools and support to help laboratories analyze their specific needs and estimate the potential impact of automation on productivity, quality, and cost-effectiveness.

What support and training does Copan provide for laboratories implementing WASP®?

Copan works closely with laboratories to ensure a smooth implementation of WASP® and other automation solutions. This includes on-site training, application support, and ongoing collaboration to optimize workflows and adapt to the laboratory’s evolving needs:

- On-site installation and validation support

- Training for laboratory staff on system operation and maintenance

- Ongoing technical support and troubleshooting

- Access to software updates and enhancements

- Collaboration with laboratory teams to optimize workflows and protocols

How does WASP® fit into Copan's vision of full laboratory automation?

WASP® is the first step in Copan’s Full Laboratory Automation ecosystem. It directly links with WASPLab®, a suite of automated specimen processing, incubation, imaging, and interpretation tools, enabling the digitalization of microbiology workflows.